-

© STOFF2/Kerstin Reisch

19.08.2024The small, subtle intermediate step

The famous ‘Gründer-Garage’, in which start-ups take their first steps, can sometimes also be a kitchen. This was certainly the case for STOFF2. In 2020, one of the two founders, electrical engineer Andrew Zwinkels, conducted his first experiments in a whisky glass. The young company has continued to grow ever since and now has around 30 employees. Located at the Berlin Zukunftsort site ‘Berlin TXL – Urban Tech Republic’, the team is developing a new technology for producing green hydrogen: STOFF2 wants to bring the ‘Zinc Intermediate-step Electrolyser’ (ZZE) to market maturity and is working closely with the Technische Universität Berlin (TU Berlin) to achieve this. In this Brain City interview, Christian Friebe, Head of Public Affairs, explains what ZZE is and why the high-tech product from STOFF2 could revolutionise the use of wind and solar energy.

Mr Friebe, what’s special about the STOFF2 product?

Standard electrolysers – devices which use electricity to split water into hydrogen and oxygen – produce green hydrogen whenever renewable power is available. This means that traditional electrolysers can only produce hydrogen if fluctuating renewable energies are also available at the same time. Our system combines electrolysis and an energy storage device in one. In other words, green electricity is initially charged for four hours in each cell of our Zinc Intermediate-step Electrolyser. The system safely stores the energy absorbed for hours – even days – in the form of solid zinc. In the third step, green hydrogen is then discharged as required for anywhere between 12 and 24 hours.

What specific benefits does this system offer customers?

There are many benefits: firstly, our ZZE systems use the ‘intermediate step’ of the energy storage device to charge the renewable wind and solar power only when it is being produced in excess – and therefore much cheaper. Electricity procurement is a major cost factor when it comes to green hydrogen. Secondly, they can also exclusively charge renewable power that would otherwise be ‘capped’ by the network operator, so which wouldn’t be generated at all. This renewable power would otherwise be lost due to a lack of network capacity. Additionally, our systems produce green hydrogen on a delayed basis, when the customer actually needs it. This could also involve a permanent supply 24/7. Such flexibility when it comes to hydrogen production is unique and particularly beneficial for industrial companies.

How did the business idea come about?

Our founders, Andrew Zwinkels and Alexander Voigt, had already spent years working on the development and scaling of alternative energy technologies. The rise in renewable energies has also increased the demand for energy storage solutions. Both have many years of experience with battery storage devices, high-temperature storage units and can now collect zinc. In fact, Andrew Zwinkels performed one of the first experiments with a whisky glass in his kitchen. If you visit us in Tegel, you’ll see a whole range of prototypes from recent years. With around 30 employees, we are now working on the final steps to batch produce an electrolyser that will fit inside a six metre-long container and which can be used in an industrial setting.

What were and remain the biggest challenges when founding and developing STOFF2?

A technology company is usually more capital-intensive than other businesses and needs more time to develop its product to an industrially relevant scale. Developing technologies is expensive and therefore needs to happen as quickly as possible. At the same time, the product should be stable once finished, operate safely and also be cost-effective to produce. We’ve been navigating this terrain since the day the company was founded.

How have you financed the start-up so far?

Through the founders and various strategic investors. During the previous scaling phases, we also benefited greatly from public funding by the Federal Ministry of Education and Research (BMBF) and the Federal Ministry for Economic Affairs and Climate Action (BMWK). However, it’s not just the financial support that’s important to us but also the external validation of our work. The progression and feasibility of our system were continually reviewed and followed by external experts at the German Aerospace Centre (DLR) and Projektträger Jülich (PtJ) at the time of the grant application as well as during the funding period.

-

© STOFF2/Kerstin Reisch

© STOFF2/Kerstin Reisch

The STOFF2 TEAM with pet. Christian Friebe in the top row (3rd from right). -

© STOFF2/Kerstin Reisch

© STOFF2/Kerstin Reisch

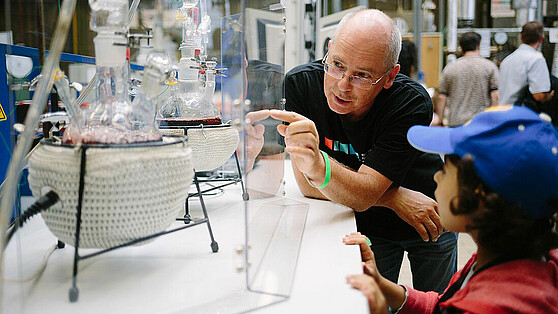

STOFF2 founder and Technical Director Andrew Zwinkels presents the "Zinc Intermedate-step Electrolyser" to EU Climate Protection Commissioner Wopke Koekstra.

Do you have any customers yet?

We’re currently in talks with a number of potential customers. These include project developers, often from the field of wind and solar farms, energy providers who are also interested in electricity and gas infrastructures, and industrial companies that require a reliable supply of green hydrogen around the clock. There is a lot of interest in our product, particularly among those who have already implemented hydrogen projects in the past and have some experience in this area. At the same time, all of these customers want to see the technology in action. That’s why we are currently testing it intensively in collaboration with other players in the energy industry: We want to install our system in an industrial environment for the first time as part of the research project Hydrogen Terminal Braunschweig, which we are carrying out in partnership with Steinbeis-Innovationszentrum energieplus (SIZ). STOFF2 is also involved in the European REFORMERS project. A Renewable Energy Valley is being set up in the Dutch city of Alkmaar. The STOFF2 electrolyser will be installed there in 2026 and heavily tested along with other alternative energy innovations and infrastructures.

Do you also have research links with Berlin’s universities and scientific institutes?

We are working closely with the TU Berlin at the Tegel site as part of the joint project ZZE-GREEN-H2 to implement the initial final scaling step. This will increase the technological maturity of our product and thus form the basis for series production.

Why is Berlin a good location for start-ups with a scientific background?

Berlin – particularly the .GUT Community (link in German only) in the Urban Tech Republic – is a great location for developing climate protection technologies. Start-ups convene here that also need workshops to build prototypes. There’s a community area on site that is heavily used by local companies like us as well as external organisations for events. There are now a good 20 start-ups here that cover all sorts of areas from sustainable building materials and high-temperature energy storage devices to solar roof tiles, algae and drones. This community has a presence far beyond Berlin and Germany.

What vision do you have for STOFF2 – and where do you want the company to be in five years?

In five years’ time we want our technology to make a significant contribution to the energy transition across all sectors. Until then, we will be focusing on industrial series production of our ZZE electrolyser at multiple sites and implementing a number of green hydrogen projects together with our partners and customers in Germany and Europe.

Interview: Ernestine von der Osten-Sacken

More information

More Stories

-

Startup Facts & Events

Photo credit: © Samuel Stuart Hollenshead / NYU Photo Bureau

Startup Facts & EventsNew York University becomes a strategic partner university of Humboldt-Universität zu Berlin.→

Photo credit: © Samuel Stuart Hollenshead / NYU Photo Bureau

Startup Facts & EventsNew York University becomes a strategic partner university of Humboldt-Universität zu Berlin.→New York University becomes a strategic partner university of Humboldt-Universität zu Berlin

-

Insights Transfer – Stories

© Nikolaus Brade

Insights Transfer – StoriesWith the project “Multisensory in Dialogue and Artistic Practice”, UdK Berlin and Folkwang are sending a strong signal for the future of artistic…→

© Nikolaus Brade

Insights Transfer – StoriesWith the project “Multisensory in Dialogue and Artistic Practice”, UdK Berlin and Folkwang are sending a strong signal for the future of artistic…→Unlocking Joint Potential

-

Transfer – Stories

© Shutterstock / Studio Romantic

Transfer – StoriesCan elderly people regain independence through targeted exercise? Brain City Ambassador Prof. Dr. Uwe Bettig of ASH Berlin examined this question in…→

© Shutterstock / Studio Romantic

Transfer – StoriesCan elderly people regain independence through targeted exercise? Brain City Ambassador Prof. Dr. Uwe Bettig of ASH Berlin examined this question in…→Fit for home again

-

Facts & Events Transfer – Stories

© Agentur Medienlabor / Stefan Schubert

Facts & Events Transfer – StoriesFive companies from the capital region were honoured for their visionary ideas and products, and another received a special award.→

© Agentur Medienlabor / Stefan Schubert

Facts & Events Transfer – StoriesFive companies from the capital region were honoured for their visionary ideas and products, and another received a special award.→Berlin Brandenburg Innovation Award 2025 – The Winners

-

Insights Transfer – Stories

© TU Berlin/Felix Noak

Insights Transfer – StoriesProf. Dr. Giuseppe Caire, at TU Berlin, is working on a new transmission method that could revolutionize wireless communication completely.→

© TU Berlin/Felix Noak

Insights Transfer – StoriesProf. Dr. Giuseppe Caire, at TU Berlin, is working on a new transmission method that could revolutionize wireless communication completely.→Rethinking Wireless Communication

-

Insights Transfer – Stories

© HTW Berlin/Alexander Rentsch

Insights Transfer – StoriesIn January 2025, the European University Alliance EUonAIR was launched. More about this unique alliance tells us Brain City Ambassador Prof. Dr.…→

© HTW Berlin/Alexander Rentsch

Insights Transfer – StoriesIn January 2025, the European University Alliance EUonAIR was launched. More about this unique alliance tells us Brain City Ambassador Prof. Dr.…→"We don't want to reinvent the wheel”

-

Facts & Events Transfer – Stories

© Christian Kielmann

Facts & Events Transfer – StoriesEurope’s largest laboratory infrastructure for transfer teams in the field of Green Chemistry is being built on the campus of TU Berlin. The “Chemical…→

© Christian Kielmann

Facts & Events Transfer – StoriesEurope’s largest laboratory infrastructure for transfer teams in the field of Green Chemistry is being built on the campus of TU Berlin. The “Chemical…→Construction Kick-off: „Chemical Invention Factory“

-

Facts & Events Transfer – Stories

© TU Berlin / allefarben-foto

Facts & Events Transfer – StoriesDrone logistics, recycling of building material and wastewater reuse: these ideas are to be tested in so-called “Reallaboren” (Real-World…→

© TU Berlin / allefarben-foto

Facts & Events Transfer – StoriesDrone logistics, recycling of building material and wastewater reuse: these ideas are to be tested in so-called “Reallaboren” (Real-World…→Three Real-World Laboratories are being Launched in Berlin

-

Facts & Events Transfer – Stories

© Stefan Klenke / HU Berlin

Facts & Events Transfer – StoriesBerlin-based battery researcher Prof. Dr. Philipp Adelhelm has been awarded the 2024 Berlin Science Award. Prof. Dr. Inka Mai from TU Berlin received…→

© Stefan Klenke / HU Berlin

Facts & Events Transfer – StoriesBerlin-based battery researcher Prof. Dr. Philipp Adelhelm has been awarded the 2024 Berlin Science Award. Prof. Dr. Inka Mai from TU Berlin received…→Prof. Dr. Philipp Adelhelm honored with Berlin Science Award

-

Insights Transfer – Stories

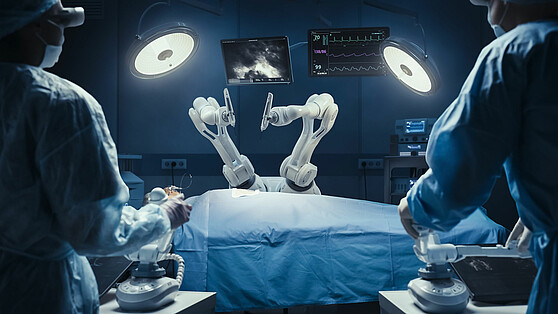

© Gorodenkoff / Shutterstock.com

Insights Transfer – StoriesBrain City Interview: Prof. Dr. Petra Ritter gives an insight into the cross-border project TEF-Health.→

© Gorodenkoff / Shutterstock.com

Insights Transfer – StoriesBrain City Interview: Prof. Dr. Petra Ritter gives an insight into the cross-border project TEF-Health.→European test infrastructure for AI in healthcare

-

Insights Transfer – Stories

© HTW Berlin/Alexander Rentsch

Insights Transfer – StoriesThe KI-Werkstatt at the HTW Berlin brings together the university’s expertise in an interdisciplinary manner to research the practical use of AI.→

© HTW Berlin/Alexander Rentsch

Insights Transfer – StoriesThe KI-Werkstatt at the HTW Berlin brings together the university’s expertise in an interdisciplinary manner to research the practical use of AI.→Strengthening generative AI in research and teaching

-

Facts & Events Transfer – Stories

© DLR (CC BY-NC-ND 3.0)

Facts & Events Transfer – StoriesWith the newly founded institute, the German Aerospace Center is pooling its expertise in the field of space instruments and space research in Brain…→

© DLR (CC BY-NC-ND 3.0)

Facts & Events Transfer – StoriesWith the newly founded institute, the German Aerospace Center is pooling its expertise in the field of space instruments and space research in Brain…→New DLR Institute of Space Research

-

Startup Transfer – Stories

© theion

Startup Transfer – StoriesThe start-up theion wants to revolutionise the battery market and accelerate the energy transition with a new technology in Brain City Berlin.→

© theion

Startup Transfer – StoriesThe start-up theion wants to revolutionise the battery market and accelerate the energy transition with a new technology in Brain City Berlin.→“Batteries made in Germany, made in Berlin”

-

Insights Transfer – Stories

© Berlin University Alliance / Stefan Klenke

Insights Transfer – StoriesWith the innovate! lab, the Berlin University Alliance (BUA) aims to bring cutting-edge research into practice quickly and purposefully. Dr.…→

© Berlin University Alliance / Stefan Klenke

Insights Transfer – StoriesWith the innovate! lab, the Berlin University Alliance (BUA) aims to bring cutting-edge research into practice quickly and purposefully. Dr.…→“Research transfer through agility”

-

Facts & Events Transfer – Stories

© Berlin Partner / eventfotografen.berlin

Facts & Events Transfer – StoriesOn March 4, a total of 19 universities, colleges and non-university research institutions signed the statutes of UNITE Sciences e.V.→

© Berlin Partner / eventfotografen.berlin

Facts & Events Transfer – StoriesOn March 4, a total of 19 universities, colleges and non-university research institutions signed the statutes of UNITE Sciences e.V.→UNITE Sciences: Accelerating technology transfer

-

Facts & Events Transfer – Stories

© IHK Berlin

Facts & Events Transfer – StoriesTU Berlin and IHK Berlin want to work closely together to promote university spin-offs and innovation in Brain City Berlin. An agreement has now been…→

© IHK Berlin

Facts & Events Transfer – StoriesTU Berlin and IHK Berlin want to work closely together to promote university spin-offs and innovation in Brain City Berlin. An agreement has now been…→Cooperation agreement between TU Berlin and IHK Berlin signed

-

Insights Transfer – Stories

© BettaF!sh/Valentin Pellio

Insights Transfer – StoriesThe start-up BettaF!sh develops and produces the world's first authentic seaweed-based fish alternatives in Brain City Berlin.→

© BettaF!sh/Valentin Pellio

Insights Transfer – StoriesThe start-up BettaF!sh develops and produces the world's first authentic seaweed-based fish alternatives in Brain City Berlin.→“We are breaking new ground with everything we do”

-

Insights Transfer – Stories

© Berlin Partner/Eventfotografen

Insights Transfer – StoriesThe research landscape in Berlin and Brandenburg is excellent but quite fragmented. The UNITE consortium aims to change that.→

© Berlin Partner/Eventfotografen

Insights Transfer – StoriesThe research landscape in Berlin and Brandenburg is excellent but quite fragmented. The UNITE consortium aims to change that.→UNITE: Fostering Synergies, Accelerating Innovations

-

Facts & Events Transfer – Stories

© Berlin Partner

Facts & Events Transfer – StoriesThe fourth Transfer Week Berlin-Brandenburg from November 25 to 29 will focus on the latest developments in regional transfer activities. 62 partner…→

© Berlin Partner

Facts & Events Transfer – StoriesThe fourth Transfer Week Berlin-Brandenburg from November 25 to 29 will focus on the latest developments in regional transfer activities. 62 partner…→The future of knowledge transfer: Transfer Week 2024

-

Insights Transfer – Stories

CCC © Michael Reinhardt

Insights Transfer – StoriesBrain City Interview with Dr. Anita Dame, Managing Director of the Climate Change Center Berlin Brandenburg.→

CCC © Michael Reinhardt

Insights Transfer – StoriesBrain City Interview with Dr. Anita Dame, Managing Director of the Climate Change Center Berlin Brandenburg.→“Climate transformation is a marathon”

-

Facts & Events Transfer – Stories

© CeRRI 2024

Facts & Events Transfer – StoriesTransfer activities and research do not compete with each other. On the contrary! This is one of the key findings of the “Transfer 1000” study…→

© CeRRI 2024

Facts & Events Transfer – StoriesTransfer activities and research do not compete with each other. On the contrary! This is one of the key findings of the “Transfer 1000” study…→„Transfer 1000“: Study on science transfer

-

Insights Transfer – Stories

© edelviz

Insights Transfer – StoriesBrain City interview with Lia Carlucci, Managing Director of the Food Campus Berlin. She tells us more about the current status of the project - and…→

© edelviz

Insights Transfer – StoriesBrain City interview with Lia Carlucci, Managing Director of the Food Campus Berlin. She tells us more about the current status of the project - and…→“Collaboration instead of competition”

-

Facts & Events Transfer – Stories

© HTW/ZfS

Facts & Events Transfer – StoriesClimate, health and sustainability – these are the main topics of Transferale. From 25 to 27 September, the science and transfer festival will be held…→

© HTW/ZfS

Facts & Events Transfer – StoriesClimate, health and sustainability – these are the main topics of Transferale. From 25 to 27 September, the science and transfer festival will be held…→Ideas for Berlin’s future

-

Insights Transfer – Stories

© WISTA Management GmbH – www.adlershof.de

Insights Transfer – StoriesThe Adlershof Science and Technology Park is the largest of Berlin’s eleven future locations. The close connection between science and business has…→

© WISTA Management GmbH – www.adlershof.de

Insights Transfer – StoriesThe Adlershof Science and Technology Park is the largest of Berlin’s eleven future locations. The close connection between science and business has…→“We thrive on proximity and exchange”

-

Insights Transfer – Stories

© Berlin Partner

Insights Transfer – StoriesThe “Additive Manufacturing Berlin Brandenburg” (AMBER) cluster aims to accelerate the transfer of results from cutting-edge research into…→

© Berlin Partner

Insights Transfer – StoriesThe “Additive Manufacturing Berlin Brandenburg” (AMBER) cluster aims to accelerate the transfer of results from cutting-edge research into…→AMBER: Networking cutting-edge research and industry

-

Insights Transfer – Stories

© Kai Müller Photography

Insights Transfer – StoriesA newspaper interview provided the impetus for founding the start-up. Brain City interview with airpuls founder Prof. Dr.-Ing. habil. Slawomir…→

© Kai Müller Photography

Insights Transfer – StoriesA newspaper interview provided the impetus for founding the start-up. Brain City interview with airpuls founder Prof. Dr.-Ing. habil. Slawomir…→airpuls: 5G solutions from research

-

Insights Transfer – Stories

Shutterstock © optimarc

Insights Transfer – StoriesWith a new transfer certificate, the TU Berlin certifies practical skills for students who have dealt with methods and issues of knowledge and…→

Shutterstock © optimarc

Insights Transfer – StoriesWith a new transfer certificate, the TU Berlin certifies practical skills for students who have dealt with methods and issues of knowledge and…→Thinking outside the box

-

Insights Transfer – Stories Innovations

© Berlin Partner

Insights Transfer – Stories InnovationsQuantum technology is considered to be the next big technological leap. The Brain City Berlin offers ideal conditions for this.→

© Berlin Partner

Insights Transfer – Stories InnovationsQuantum technology is considered to be the next big technological leap. The Brain City Berlin offers ideal conditions for this.→BERLIN QUANTUM: a new initiative for quantum technologies

-

Insights Transfer – Stories

Design © Sarah Engler; Foto © Alexander Bob

Insights Transfer – StoriesBrain City Interview with Prof. Dr. Uwe Bettig. As Professor of Management and Business Administration at ASH Berlin, he heads the IFAF project…→

Design © Sarah Engler; Foto © Alexander Bob

Insights Transfer – StoriesBrain City Interview with Prof. Dr. Uwe Bettig. As Professor of Management and Business Administration at ASH Berlin, he heads the IFAF project…→Many creative ideas and approaches

-

Insights Transfer – Stories

© Ivar Veermae

Insights Transfer – StoriesAt EINS in Berlin-Charlottenburg, the TU Berlin supports start-ups that meet global challenges sustainably in three ways. Universities and colleges…→

© Ivar Veermae

Insights Transfer – StoriesAt EINS in Berlin-Charlottenburg, the TU Berlin supports start-ups that meet global challenges sustainably in three ways. Universities and colleges…→Economical, ecological, social

-

Facts & Events Transfer – Stories

TU Berlin © Felix Noak

Facts & Events Transfer – StoriesInterdisciplinary research teams have until 29 April to submit their proposals for the Next Grand Challenge initiative of the Berlin University…→

TU Berlin © Felix Noak

Facts & Events Transfer – StoriesInterdisciplinary research teams have until 29 April to submit their proposals for the Next Grand Challenge initiative of the Berlin University…→Next Grand Challenge: apply now!

-

Facts & Events Transfer – Stories

© Alfred-Wegener-Institut/Micheal Gutsche (CC-BY 4.0)

Facts & Events Transfer – StoriesA special exhibition at the Deutsches Technikmuseum makes things crystal clear: There is little time left to save the Arctic.→

© Alfred-Wegener-Institut/Micheal Gutsche (CC-BY 4.0)

Facts & Events Transfer – StoriesA special exhibition at the Deutsches Technikmuseum makes things crystal clear: There is little time left to save the Arctic.→Exhibition tip: “Thin ice”

-

Insights Transfer – Stories

© Zukunftsorte Berlin

Insights Transfer – StoriesAn interview with Brain City Ambassador Steffen Terberl, Head of the Zukunftsorte Berlin office.→

© Zukunftsorte Berlin

Insights Transfer – StoriesAn interview with Brain City Ambassador Steffen Terberl, Head of the Zukunftsorte Berlin office.→“So that innovation history can be written in Berlin again”

-

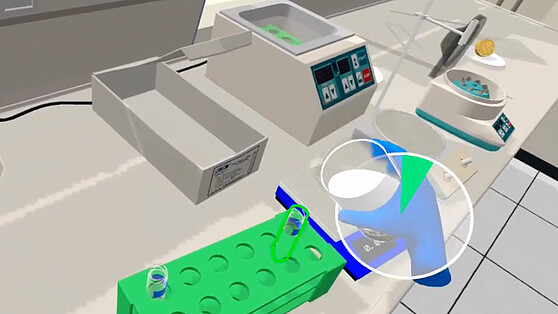

Insights Transfer – Stories

© BHT-MINT-VR-Labs

Insights Transfer – StoriesAt the MINT VR labs at the Berliner Hochschule für Technik, an interdisciplinary team works on didactic concepts for virtual laboratories and…→

© BHT-MINT-VR-Labs

Insights Transfer – StoriesAt the MINT VR labs at the Berliner Hochschule für Technik, an interdisciplinary team works on didactic concepts for virtual laboratories and…→Learning through play in the virtual bio-lab

-

Facts & Events Transfer – Stories

© BPWT

Facts & Events Transfer – StoriesWith an all-day kick-off conference in the stilwerk KantGaragen, the Transfer Week Berlin-Brandenburg 2023 starts. From 20 to 24 November, the event…→

© BPWT

Facts & Events Transfer – StoriesWith an all-day kick-off conference in the stilwerk KantGaragen, the Transfer Week Berlin-Brandenburg 2023 starts. From 20 to 24 November, the event…→“Science x Business”: Transfer Week 2023

-

Insights Transfer – Stories

© edelVIZ

Insights Transfer – StoriesFrom 2024, the Food Campus Berlin is due to be built in Berlin’s industrial Tempelhof-Ost region. The Science Park will be focussing on nutrition and…→

© edelVIZ

Insights Transfer – StoriesFrom 2024, the Food Campus Berlin is due to be built in Berlin’s industrial Tempelhof-Ost region. The Science Park will be focussing on nutrition and…→Think Tank for the food of the future

-

Insights Transfer – Stories

© Berlin Partner/Wüstenhagen

Insights Transfer – StoriesThe focus is on the science location, the science and technology transfer that is characteristic of Berlin – and of course the Brain City Ambassadors.…→

© Berlin Partner/Wüstenhagen

Insights Transfer – StoriesThe focus is on the science location, the science and technology transfer that is characteristic of Berlin – and of course the Brain City Ambassadors.…→Brain City Berlin launches new campaign motifs

-

Facts & Events Transfer – Stories

© Falling Walls Foundation

Facts & Events Transfer – StoriesBerlin Science Week is back from November 1 to 10. New this year: The ART & SCIENCE FORUM at Holzmarkt 25 is the central location of the science…→

© Falling Walls Foundation

Facts & Events Transfer – StoriesBerlin Science Week is back from November 1 to 10. New this year: The ART & SCIENCE FORUM at Holzmarkt 25 is the central location of the science…→With a focus on art & science: Berlin Science Week 2023

-

Facts & Events Transfer – Stories

© Peter Himsel/Campus Berlin-Buch GmbH

Facts & Events Transfer – StoriesBrain City Berlin has a new start-up centre: The BerlinBioCube on the Campus Berlin-Buch includes 8,000 square metres of modern laboratory and office…→

© Peter Himsel/Campus Berlin-Buch GmbH

Facts & Events Transfer – StoriesBrain City Berlin has a new start-up centre: The BerlinBioCube on the Campus Berlin-Buch includes 8,000 square metres of modern laboratory and office…→The BerlinBioCube is open

-

Insights Transfer – Stories

© Gisma

Insights Transfer – StoriesThe Gisma University of Applied Sciences has had a campus in the Brain City Berlin since 2017. More than 660 students from all over the world are…→

© Gisma

Insights Transfer – StoriesThe Gisma University of Applied Sciences has had a campus in the Brain City Berlin since 2017. More than 660 students from all over the world are…→Giving impulses to the economy

-

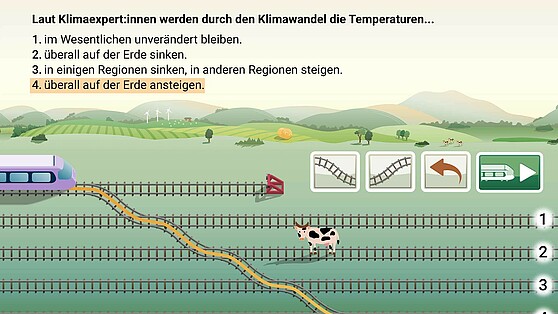

Facts & Events Transfer – Stories

© HU Berlin

Facts & Events Transfer – Stories“TRAIN 4 Science” encourages children, but also adults, to deal with climate change in a playful way. The app was developed in the Brain City Berlin…→

© HU Berlin

Facts & Events Transfer – Stories“TRAIN 4 Science” encourages children, but also adults, to deal with climate change in a playful way. The app was developed in the Brain City Berlin…→On the virtual train to a sustainable future

-

Insights Transfer – Stories

© HTW Berlin/Alexander Rentsch

Insights Transfer – StoriesAt the business and science location Berlin Schöneweide, tradition meets the ideas and solutions of tomorrow. The scientific nucleus of the area: the…→

© HTW Berlin/Alexander Rentsch

Insights Transfer – StoriesAt the business and science location Berlin Schöneweide, tradition meets the ideas and solutions of tomorrow. The scientific nucleus of the area: the…→A place of innovation and transformation

-

Insights Transfer – Stories

© vdo

Insights Transfer – StoriesProf. Dr. Claus Bull and Dipl.-Ing. Dirk Jäger at the Berliner Hochschule für Technik are investigating what street trees need to survive and how they…→

© vdo

Insights Transfer – StoriesProf. Dr. Claus Bull and Dipl.-Ing. Dirk Jäger at the Berliner Hochschule für Technik are investigating what street trees need to survive and how they…→“The trees in the city have a lot to put up with”

-

Insights Transfer – Stories

© LAS Art Foundation/Juan Camilo Roan

Insights Transfer – Stories‘Pollinator Pathmaker’ is the name given to the living work of art that is currently flowering, buzzing and fluttering in front of the Museum für…→

© LAS Art Foundation/Juan Camilo Roan

Insights Transfer – Stories‘Pollinator Pathmaker’ is the name given to the living work of art that is currently flowering, buzzing and fluttering in front of the Museum für…→Garden art from an insect’s perspective

-

Insights Transfer – Stories

© HTW Berlin/Alexander Rentsch

Insights Transfer – StoriesThe project "Zukunft findet Stadt - Hochschulnetzwerk für ein resilientes Berlin" is something that is so far unique for Berlin. Project leader Prof.…→

© HTW Berlin/Alexander Rentsch

Insights Transfer – StoriesThe project "Zukunft findet Stadt - Hochschulnetzwerk für ein resilientes Berlin" is something that is so far unique for Berlin. Project leader Prof.…→"We want innovations that are created in Berlin to be implemented here"

-

Facts & Events Transfer – Stories

© BHT/Zarko Martovic

Facts & Events Transfer – StoriesOn 17 June, more than 60 scientific and science-related institutions in the Brain City Berlin and Potsdam will open their doors for the “Long Night of…→

© BHT/Zarko Martovic

Facts & Events Transfer – StoriesOn 17 June, more than 60 scientific and science-related institutions in the Brain City Berlin and Potsdam will open their doors for the “Long Night of…→Lange Nacht der Wissenschaften 2023

-

Facts & Events Transfer – Stories

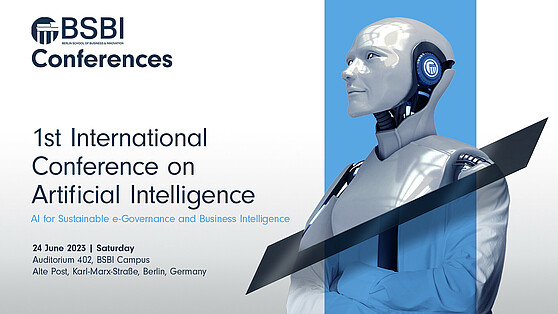

© BSBI

Facts & Events Transfer – StoriesOn 24 June the AI scene will meet in Berlin-Neukölln. The “1st International Conference on Artificial Intelligence” at the BSBI is primarily about the…→

© BSBI

Facts & Events Transfer – StoriesOn 24 June the AI scene will meet in Berlin-Neukölln. The “1st International Conference on Artificial Intelligence” at the BSBI is primarily about the…→AI Conference at the Berlin School of Business & Innovation

-

Startup Transfer – Stories

© Quantistry

Startup Transfer – StoriesThe Berlin start-up Quantistry makes chemical experiments in digital space possible with the help of Artificial Intelligence and quantum chemical…→

© Quantistry

Startup Transfer – StoriesThe Berlin start-up Quantistry makes chemical experiments in digital space possible with the help of Artificial Intelligence and quantum chemical…→The chemistry lab in the cloud

-

Insights Transfer – Stories

© Hallbauer & Fioretti

Insights Transfer – StoriesBrain City interview: Prof. Dr. Emmanuelle Charpentier, Nobel Laureate and Managing Director of the Max Planck Unit for the Science of Pathogens.→

© Hallbauer & Fioretti

Insights Transfer – StoriesBrain City interview: Prof. Dr. Emmanuelle Charpentier, Nobel Laureate and Managing Director of the Max Planck Unit for the Science of Pathogens.→"Basic research is the basis for innovation"

-

Facts & Events Transfer – Stories

© BVG/Andreas Süß

Facts & Events Transfer – StoriesWhat does an electric bus sound like? Lukas Esser, a student at Berlin University of the Arts, has developed the new sound for Germany’s electric…→

© BVG/Andreas Süß

Facts & Events Transfer – StoriesWhat does an electric bus sound like? Lukas Esser, a student at Berlin University of the Arts, has developed the new sound for Germany’s electric…→Electric sound of the future

-

Insights Transfer – Stories

© ASH Berlin/Cristián Pérez

Insights Transfer – StoriesThe acronym SAGE, in German stands for Social Work, Health, Education and Training. Prof. Bettina Völter, Rector at the ASH Berlin, tells us more…→

© ASH Berlin/Cristián Pérez

Insights Transfer – StoriesThe acronym SAGE, in German stands for Social Work, Health, Education and Training. Prof. Bettina Völter, Rector at the ASH Berlin, tells us more…→SAGE – a social three-way alliance

-

Facts & Events Transfer – Stories

© Maschinenraum

Facts & Events Transfer – StoriesThe University of Applied Sciences wants to tap additional transfer potential by means of cooperation with the nationwide network of SMEs.→

© Maschinenraum

Facts & Events Transfer – StoriesThe University of Applied Sciences wants to tap additional transfer potential by means of cooperation with the nationwide network of SMEs.→HTW Berlin cooperates with Maschinenraum

-

Insights Transfer – Stories

© QAH

Insights Transfer – StoriesThe "Zukunftsort" Technology Park Humboldthain represents the heyday of Berlin’s industrial history, but also stands for successful synergies between…→

© QAH

Insights Transfer – StoriesThe "Zukunftsort" Technology Park Humboldthain represents the heyday of Berlin’s industrial history, but also stands for successful synergies between…→Tradition meets innovation

-

Insights Transfer – Stories

© Stefan Schostok

Insights Transfer – StoriesA guest article from Brain City Ambassador Prof. Dr. Selin Arikoglu, Professor of child and youth welfare at the Catholic University of Applied Social…→

© Stefan Schostok

Insights Transfer – StoriesA guest article from Brain City Ambassador Prof. Dr. Selin Arikoglu, Professor of child and youth welfare at the Catholic University of Applied Social…→Giving a scientific voice to the relatives of prisoners

-

Facts & Events Transfer – Stories

© Berlin Partner

Facts & Events Transfer – StoriesWith a new image film Brain City Berlin starts the year 2023. Our Brain City Ambassadors are the protagonists of the video.→

© Berlin Partner

Facts & Events Transfer – StoriesWith a new image film Brain City Berlin starts the year 2023. Our Brain City Ambassadors are the protagonists of the video.→“We are Brain City Berlin”

-

Insights Transfer – Stories

© HWR Berlin/ Franziska Ihle

Insights Transfer – StoriesWith the project “KlinKe”, Prof. Dr. Silke Bustamante and her colleague Prof. Dr. Andrea Pelzeter at the HWR Berlin are researching which of the…→

© HWR Berlin/ Franziska Ihle

Insights Transfer – StoriesWith the project “KlinKe”, Prof. Dr. Silke Bustamante and her colleague Prof. Dr. Andrea Pelzeter at the HWR Berlin are researching which of the…→On the way to becoming a climate-neutral hospital

-

Facts & Events Transfer – Stories

© Transfer Week

Facts & Events Transfer – StoriesFrom 21 to 25 November, scientists can once again discuss future-oriented topics on a practical level together with companies from Berlin and…→

© Transfer Week

Facts & Events Transfer – StoriesFrom 21 to 25 November, scientists can once again discuss future-oriented topics on a practical level together with companies from Berlin and…→Providing impulses for cooperation: Transfer Week 2022

-

Facts & Events Transfer – Stories

© Falling Walls Foundation

Facts & Events Transfer – StoriesAn interview with Christine Brummer, director of Berlin Science Week.→

© Falling Walls Foundation

Facts & Events Transfer – StoriesAn interview with Christine Brummer, director of Berlin Science Week.→Opening up science for dialogue with society

-

Insights Transfer – Stories

Shutterstock © Monster Ztudio

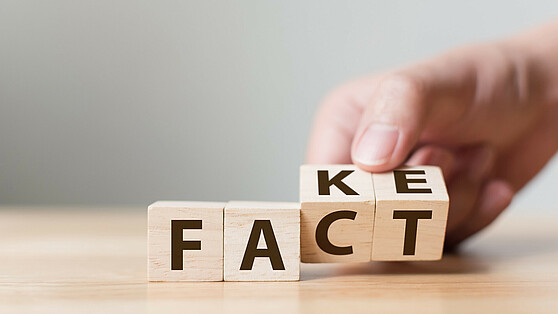

Insights Transfer – StoriesWith the help of Artificial Intelligence, the research project “news-polygraph”, anchored in the Brain City Berlin, aims to identify manipulated media…→

Shutterstock © Monster Ztudio

Insights Transfer – StoriesWith the help of Artificial Intelligence, the research project “news-polygraph”, anchored in the Brain City Berlin, aims to identify manipulated media…→“news-polygraph”: Funding by the BMBF

-

Insights Transfer – Stories

© Felix Noak

Insights Transfer – StoriesBrain City interview with Dr. phil. Thorsten Philipp, Advisor Transdisciplinary Teaching in the Office of the Vice Presidents of TU Berlin.→

© Felix Noak

Insights Transfer – StoriesBrain City interview with Dr. phil. Thorsten Philipp, Advisor Transdisciplinary Teaching in the Office of the Vice Presidents of TU Berlin.→“Everybody knows something”

-

Insights Transfer – Stories

@ Ernestine von der Osten-Sacken

Insights Transfer – StoriesListening to sounds like the bat: On "Sound Walk" with Hannes Hoelzl, sound artist and lecturer for Generative Arts/Computational Arts at the UdK…→

@ Ernestine von der Osten-Sacken

Insights Transfer – StoriesListening to sounds like the bat: On "Sound Walk" with Hannes Hoelzl, sound artist and lecturer for Generative Arts/Computational Arts at the UdK…→Seeing with the Ears

-

Transfer – Stories

Image: Shutterstock © Yurchanka Siarhei

Transfer – StoriesThe Berlin AI Competence Centre BIFOLD will receive 22 million Euro annually in the future from the Federal government and the State of Berlin.→

Image: Shutterstock © Yurchanka Siarhei

Transfer – StoriesThe Berlin AI Competence Centre BIFOLD will receive 22 million Euro annually in the future from the Federal government and the State of Berlin.→Millions in Funding for AI Research in Berlin

-

Transfer – Stories

Falling Walls Foundation © Judith Schalansky

Transfer – StoriesFrom November 1st through the 10th, the scientific world comes together again in Brain City Berlin. Scientific institutions or organisations can still…→

Falling Walls Foundation © Judith Schalansky

Transfer – StoriesFrom November 1st through the 10th, the scientific world comes together again in Brain City Berlin. Scientific institutions or organisations can still…→“Dare to know”: Berlin Science Week 2022

-

Transfer – Stories

EUREF AG©Gasometertour.de

Transfer – StoriesOn the site of the EUREF-Campus in Berlin-Schoeneberg the transfer of knowledge works particularly impressively.→

EUREF AG©Gasometertour.de

Transfer – StoriesOn the site of the EUREF-Campus in Berlin-Schoeneberg the transfer of knowledge works particularly impressively.→Hands-on Energy Transition

-

Transfer – Stories

© SCC Events/Norbert Wilhelmi

Transfer – StoriesInterview with Brain City Ambassador Prof. Dr. Gabriele Mielke, Vice President of the VICTORIA | International University of Applied Sciences and also…→

© SCC Events/Norbert Wilhelmi

Transfer – StoriesInterview with Brain City Ambassador Prof. Dr. Gabriele Mielke, Vice President of the VICTORIA | International University of Applied Sciences and also…→"Major Events Affect Life in the City on Different Levels”

-

Transfer – Stories

Photo: Ernestine von der Osten-Sacken (vdo)

Transfer – StoriesThe Charlottenburg Innovation Centre CHIC hosts around 50 start-ups. Situated at Brain City Berlin’s “Zukunftsort” Campus Charlottenburg, the CHIC…→

Photo: Ernestine von der Osten-Sacken (vdo)

Transfer – StoriesThe Charlottenburg Innovation Centre CHIC hosts around 50 start-ups. Situated at Brain City Berlin’s “Zukunftsort” Campus Charlottenburg, the CHIC…→CHIC - Business Incubator at a "Zukunftsort’"

-

Transfer – Stories

Photo: Mall Anders/Matthew Crabbe

Transfer – Stories“Mall Anders” is an open learning laboratory which was launched by the FU Berlin, HU Berlin, TU Berlin and Charité – Universitätsmedizin Berlin in a…→

Photo: Mall Anders/Matthew Crabbe

Transfer – Stories“Mall Anders” is an open learning laboratory which was launched by the FU Berlin, HU Berlin, TU Berlin and Charité – Universitätsmedizin Berlin in a…→Science in a Shopping Centre

-

Transfer – Stories

BHT/Martin Gasch

Transfer – StoriesInterview: Brain City Ambassador Dr-Ing. Ivo Boblan, Professor of the Humanoid Robotics Study Programme at the Berliner Hochschule für Technik, and…→

BHT/Martin Gasch

Transfer – StoriesInterview: Brain City Ambassador Dr-Ing. Ivo Boblan, Professor of the Humanoid Robotics Study Programme at the Berliner Hochschule für Technik, and…→“Robots Can Save us a Great Deal of Work”

-

Transfer – Stories

(Left to right) Prof. Christian Matzdorf, Police commissioner Turgay Akkaya, Stefan Graf Finck von Finckenstein, Photo: HWR Berlin / Sylke Schumann

Transfer – StoriesPolice commissioner Turgay Akkaya has developed an anti-stalking app as part of his Bachelor’s project at the HWR Berlin. At the beginning of January…→

(Left to right) Prof. Christian Matzdorf, Police commissioner Turgay Akkaya, Stefan Graf Finck von Finckenstein, Photo: HWR Berlin / Sylke Schumann

Transfer – StoriesPolice commissioner Turgay Akkaya has developed an anti-stalking app as part of his Bachelor’s project at the HWR Berlin. At the beginning of January…→A Preventive App Against Stalking

-

Transfer – Stories

(From left to right) Steffen Terberl/FU Berlin; Prof. Dr. Hannes Rothe/ICN Business School, photo: Ernestine von der Osten-Sacken

Transfer – StoriesIn the BioTech sector, the Berlin region is not making full use of its innovation potential. This is the conclusion of the “Deep Tech Futures Report…→

(From left to right) Steffen Terberl/FU Berlin; Prof. Dr. Hannes Rothe/ICN Business School, photo: Ernestine von der Osten-Sacken

Transfer – StoriesIn the BioTech sector, the Berlin region is not making full use of its innovation potential. This is the conclusion of the “Deep Tech Futures Report…→“BioTech does not get up and running on its own”

-

Transfer – Stories

Photo: Christina Lüdtke (private source)

Transfer – StoriesFour universities, one network: The network “Science & Startups” groups the start-up services of the universities united in the Berlin University…→

Photo: Christina Lüdtke (private source)

Transfer – StoriesFour universities, one network: The network “Science & Startups” groups the start-up services of the universities united in the Berlin University…→Wide-ranging Support for University Start-ups

-

Transfer – Stories

Photo: private

Transfer – StoriesA guest contribution by Brain City Ambassador Dr. Anna Klippstein, professor of finance and Eliyahu Mätzschker, student at Touro College Berlin.→

Photo: private

Transfer – StoriesA guest contribution by Brain City Ambassador Dr. Anna Klippstein, professor of finance and Eliyahu Mätzschker, student at Touro College Berlin.→The Pandemic and its Impact on the Capital Market

-

Transfer – Stories

Credit: André Bakker

Transfer – StoriesA guest contribution by Brain City Ambassador Prof. Dr Anabel Ternès von Hattburg, Professor for International Business Administration at the SRH…→

Credit: André Bakker

Transfer – StoriesA guest contribution by Brain City Ambassador Prof. Dr Anabel Ternès von Hattburg, Professor for International Business Administration at the SRH…→Getting on Board with Digitality

-

Transfer – Stories

Swen Hutter (Foto: David Ausserhofer), Gesine Höltmann (Foto: Martina Sander)

Transfer – StoriesA guest contribution by Gesine Höltmann, research assistant and Swen Hutter, Deputy Director at the Centre for Civil Society Research.→

Swen Hutter (Foto: David Ausserhofer), Gesine Höltmann (Foto: Martina Sander)

Transfer – StoriesA guest contribution by Gesine Höltmann, research assistant and Swen Hutter, Deputy Director at the Centre for Civil Society Research.→Polarisation and Cohesion in the Corona Crisis: a Look at Civil Society

-

Transfer – Stories

Foto: "Lucid Dream", Elena Kunau and Mariya Yordanova

Transfer – StoriesARTIFICIAL REALITY – VIRTUAL INTELLIGENCE is the name of an exhibition that can be seen from 8 to 12 September as part of Ars Electronica Garden…→

Foto: "Lucid Dream", Elena Kunau and Mariya Yordanova

Transfer – StoriesARTIFICIAL REALITY – VIRTUAL INTELLIGENCE is the name of an exhibition that can be seen from 8 to 12 September as part of Ars Electronica Garden…→Interaction via Emotion

-

Transfer – Stories

Credit: Peter Himsel/Campus Berlin-Buch GmbH

Transfer – StoriesThe Campus Berlin-Buch in the north of Brain City Berlin has grown to become one of Europe’s largest business and research centres for life sciences.→

Credit: Peter Himsel/Campus Berlin-Buch GmbH

Transfer – StoriesThe Campus Berlin-Buch in the north of Brain City Berlin has grown to become one of Europe’s largest business and research centres for life sciences.→A Vibrant Healthcare Network

-

Transfer – Stories

Credit: Markus Krutzik

Transfer – StoriesDr. Markus Krutzik, Head of the Joint Lab Integrated Quantum Sensors (IQS), on the "Wissenschaft trifft Wirtschaft" (Science Meets Business") event…→

Credit: Markus Krutzik

Transfer – StoriesDr. Markus Krutzik, Head of the Joint Lab Integrated Quantum Sensors (IQS), on the "Wissenschaft trifft Wirtschaft" (Science Meets Business") event…→"I am Fascinated by the Possibilities of Quantum Sensors"

-

Transfer – Stories

Foto: ESCP Business School Berlin

Transfer – StoriesWhat to do when distance is suddenly the order of the day? A guest contribution by Dr. René Mauer, Professor of Entrepreneurship und Innovation at…→

Foto: ESCP Business School Berlin

Transfer – StoriesWhat to do when distance is suddenly the order of the day? A guest contribution by Dr. René Mauer, Professor of Entrepreneurship und Innovation at…→Using Whiteboards to Combat Digital Fatigue

-

Transfer – Stories

Credit: Alexander Rentsch/HTW Berlin

Transfer – StoriesBrain City Ambassador Prof. Dr. Florian Koch of HTW Berlin brings together science, business and civil society in his research.→

Credit: Alexander Rentsch/HTW Berlin

Transfer – StoriesBrain City Ambassador Prof. Dr. Florian Koch of HTW Berlin brings together science, business and civil society in his research.→“Increasing Urbanisation also Creates Opportunities”

-

Transfer – Stories

Credit: Rudolf Grillborzer

Transfer – StoriesGuest contribution by Brain City Ambassador Dr.-Ing. Onur Günlü, Technische Universität Berlin.→

Credit: Rudolf Grillborzer

Transfer – StoriesGuest contribution by Brain City Ambassador Dr.-Ing. Onur Günlü, Technische Universität Berlin.→Exploring the "ultimate limits"

-

Transfer – Stories

Credt: Startup Incubator Berlin

Transfer – StoriesThe Startup Incubator Berlin at the Berlin School of Economics and Law is particularly successful in supporting founder teams – as proved by the fact…→

Credt: Startup Incubator Berlin

Transfer – StoriesThe Startup Incubator Berlin at the Berlin School of Economics and Law is particularly successful in supporting founder teams – as proved by the fact…→“We Bring Ideas to Market”

-

Transfer – Stories

Credit: Mimi Thian on Unsolash

Transfer – StoriesGuest Contribution by Brain City Ambassador Dr. Petyo Budakov, University of Europe for Applied Sciences.→

Credit: Mimi Thian on Unsolash

Transfer – StoriesGuest Contribution by Brain City Ambassador Dr. Petyo Budakov, University of Europe for Applied Sciences.→“Proudly presenting Brain City Berlin in 2020”

-

Transfer – Stories

Susanne Plaumann (private)

Transfer – StoriesInterview with Brain City Ambassador Susanne Plaumann M.A., Central women's representative at the Beuth University of Applied Sciences Berlin.→

Susanne Plaumann (private)

Transfer – StoriesInterview with Brain City Ambassador Susanne Plaumann M.A., Central women's representative at the Beuth University of Applied Sciences Berlin.→“Careers are now easier to plan for women scientists”

-

Transfer – Stories

Adi Goldstein auf Unsplash

Transfer – StoriesStadtManufaktur Berlin conceptually unites research projects of the TU Berlin under a single roof. The long-term goal of this “open laboratory…→

Adi Goldstein auf Unsplash

Transfer – StoriesStadtManufaktur Berlin conceptually unites research projects of the TU Berlin under a single roof. The long-term goal of this “open laboratory…→Science in Dialogue with the City

-

Transfer – Stories

Falk Weiß

Transfer – StoriesThe knowledge portal “humboldts17” presents current research on the subject of sustainability and welcomes open dialogue with the general public. The…→

Falk Weiß

Transfer – StoriesThe knowledge portal “humboldts17” presents current research on the subject of sustainability and welcomes open dialogue with the general public. The…→17 Goals for the Future

-

Transfer – Stories

Foto: Olga Makarova privat

Transfer – StoriesBrain City Ambassador Olga Makarova reflects on being a microbiologist during the pandemic, and the urgent need for microbiology literacy in society.→

Foto: Olga Makarova privat

Transfer – StoriesBrain City Ambassador Olga Makarova reflects on being a microbiologist during the pandemic, and the urgent need for microbiology literacy in society.→Guest Contribution: COVID-19 and microbiology literacy

-

Transfer – Stories

HIIG

Transfer – StoriesBrain City-Interview with Prof. Dr. Wolfgang Schulz, Research Director at the Alexander von Humboldt Institute for Internet and Society (HIIG).→

HIIG

Transfer – StoriesBrain City-Interview with Prof. Dr. Wolfgang Schulz, Research Director at the Alexander von Humboldt Institute for Internet and Society (HIIG).→“A sustainable goal of our work is to make clear what the technology can actually do”

-

Transfer – Stories

HTW Berlin

Transfer – StoriesAn interview with Brain City Ambassador Prof. Dr. Kai Reinhardt. On October 28, he will be speaking at the second SpreeTalk at HTW University of…→

HTW Berlin

Transfer – StoriesAn interview with Brain City Ambassador Prof. Dr. Kai Reinhardt. On October 28, he will be speaking at the second SpreeTalk at HTW University of…→“The pandemic has been a catalyst for digitalization”

-

Transfer – Stories

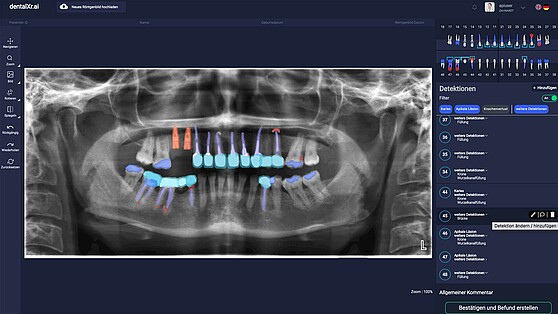

dentalXr.ai

Transfer – StoriesdentalXrai is the first dental start-up to be spun off the Charité. It was launched via the accelerator of the Berlin Institute of Health (BIH). We…→

dentalXr.ai

Transfer – StoriesdentalXrai is the first dental start-up to be spun off the Charité. It was launched via the accelerator of the Berlin Institute of Health (BIH). We…→Artificial intelligence in the fight against tooth decay

-

Transfer – Stories

Anna Raysyan (private)

Transfer – StoriesBrain City Ambassador Anna Raysyan has been living in Berlin for 3,5 years now. She is a PhD student at the Bundesanstalt für Materialforschung und…→

Anna Raysyan (private)

Transfer – StoriesBrain City Ambassador Anna Raysyan has been living in Berlin for 3,5 years now. She is a PhD student at the Bundesanstalt für Materialforschung und…→Guest Contribution: “Berlin likes the bold!”

-

Transfer – Stories

©Berlin Partner für Wirtschaft und Technologie

Transfer – StoriesMany top-class researchers and scientists are being attracted to Brain City Berlin every year. The Dual Career Network Berlin helps partners of…→

©Berlin Partner für Wirtschaft und Technologie

Transfer – StoriesMany top-class researchers and scientists are being attracted to Brain City Berlin every year. The Dual Career Network Berlin helps partners of…→Dual Career Network Berlin: getting a good start in Berlin

-

Transfer – Stories

©Matthias Picket

Transfer – StoriesDr. Anne Schreiter, Managing Director of the German Scholars Organization (GSO), reveals in the Brain City interview what alternative career…→

©Matthias Picket

Transfer – StoriesDr. Anne Schreiter, Managing Director of the German Scholars Organization (GSO), reveals in the Brain City interview what alternative career…→"Science is not just about research"

-

Transfer – Stories

© Pocky Lee on Unsplash

Transfer – StoriesMatches in front of empty stadiums, virtual marathons, and many postponed events. Brain City Ambassador Professor Gabriele Mielke is tracking the…→

© Pocky Lee on Unsplash

Transfer – StoriesMatches in front of empty stadiums, virtual marathons, and many postponed events. Brain City Ambassador Professor Gabriele Mielke is tracking the…→"Now is the time for innovators"

-

Transfer – Stories

© AW Creative on Unsplash

Transfer – StoriesJuggling a degree course or teaching with the extra burden of the care of children or other family members is not an easy task. Both students and…→

© AW Creative on Unsplash

Transfer – StoriesJuggling a degree course or teaching with the extra burden of the care of children or other family members is not an easy task. Both students and…→From “Zoo School” to “Maternity Protection”: family-friendly universities

-

Transfer – Stories

© HTW Berlin / Nikolas Fahlbusch

Transfer – StoriesTeaching is currently only taking place online. Guest author Dr Dorothee Haffner, professor for Museology at HTW Berlin - University of Applied…→

© HTW Berlin / Nikolas Fahlbusch

Transfer – StoriesTeaching is currently only taking place online. Guest author Dr Dorothee Haffner, professor for Museology at HTW Berlin - University of Applied…→Guest contribution: "Online teaching is more engaging than I thought"

-

Transfer – Stories

Franziska Sattler

Transfer – StoriesIn the interview: Brain City ambassador Franziska Sattler on her series of events "Kaffeeklatsch mit Wissenschaft" (Talking Science over Coffee) at…→

Franziska Sattler

Transfer – StoriesIn the interview: Brain City ambassador Franziska Sattler on her series of events "Kaffeeklatsch mit Wissenschaft" (Talking Science over Coffee) at…→"Science needs the trust of society"

-

Transfer – Stories

Fotocredit: Ortner & Ortner / Siemens

Transfer – StoriesSiemensstadt 2.0 is a place of the future. The Berlin Senate has approved 9.9 million euros for the first research project "Electrical Drive…→

Fotocredit: Ortner & Ortner / Siemens

Transfer – StoriesSiemensstadt 2.0 is a place of the future. The Berlin Senate has approved 9.9 million euros for the first research project "Electrical Drive…→Siemensstadt 2.0: Research and industry closely linked

-

Transfer – Stories

©Credit Silke Oßwald/FMP

Transfer – StoriesBrain City interview: Professor Dr. Volker Haucke, Director at the Leibniz-Forschungsinstitut für Molekulare Pharmakologie (FMP) and Professor of…→

©Credit Silke Oßwald/FMP

Transfer – StoriesBrain City interview: Professor Dr. Volker Haucke, Director at the Leibniz-Forschungsinstitut für Molekulare Pharmakologie (FMP) and Professor of…→In the balancing act between detail and overall concept

-

Transfer – Stories

© hj barraza/Unsplash

Transfer – StoriesOur guest author Dr Barbara Schäuble is Professor for Diversity-Conscious Approaches in the Theory and Practice of Social Work at ASH Berlin and a…→

© hj barraza/Unsplash

Transfer – StoriesOur guest author Dr Barbara Schäuble is Professor for Diversity-Conscious Approaches in the Theory and Practice of Social Work at ASH Berlin and a…→Guest contribution: A sudden change of course - classes moved online

-

Transfer – Stories

©DexLeChem

Transfer – StoriesLaunching a start-up while at university? Sonja Jost's success shows the way. Together with three fellow students, she founded DexLeChem after…→

©DexLeChem

Transfer – StoriesLaunching a start-up while at university? Sonja Jost's success shows the way. Together with three fellow students, she founded DexLeChem after…→"Bringing new knowledge to the market is very important to us"

-

Transfer – Stories

©Ivar Veermäe / Centre for Entrepreneurship

Transfer – StoriesBrain City Berlin is the German capital of start-ups. Many young companies have successfully been founded through Berlin and Brandenburg based…→

©Ivar Veermäe / Centre for Entrepreneurship

Transfer – StoriesBrain City Berlin is the German capital of start-ups. Many young companies have successfully been founded through Berlin and Brandenburg based…→"Society in particular benefits from high-tech start-ups" - university survey enters its third round

-

Transfer – Stories

©BIH|Thomas Rafalzyk

Transfer – StoriesAt the Berlin Institute of Health (BIH) the main focus is on "translational research" - the transfer of findings from the research lab into clinical…→

©BIH|Thomas Rafalzyk

Transfer – StoriesAt the Berlin Institute of Health (BIH) the main focus is on "translational research" - the transfer of findings from the research lab into clinical…→“There are now many great female scientists, achieving great things”

-

Transfer – Stories

©fotografixx - istockphoto.com

Transfer – StoriesIn the digital age learning behaviour changes profoundly. It is student-centered and technology rich. As a member of the Erasmus+ funded project…→

©fotografixx - istockphoto.com

Transfer – StoriesIn the digital age learning behaviour changes profoundly. It is student-centered and technology rich. As a member of the Erasmus+ funded project…→Exploring the future of learning

-

Transfer – Stories

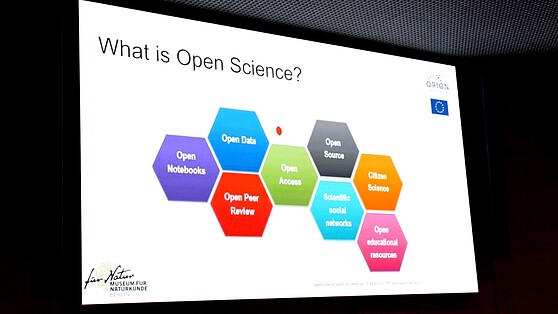

© Brain City Berlin

Transfer – StoriesResearch results quickly and easily accessible online: The Open Access movement is campaigning for a paradigm shift in the field of publications and…→

© Brain City Berlin

Transfer – StoriesResearch results quickly and easily accessible online: The Open Access movement is campaigning for a paradigm shift in the field of publications and…→Open Access: free knowledge for everyone

-

Transfer – Stories

©ESCP EUROPE

Transfer – Stories29.10.2019 | Professor Andreas Kaplan is a Brain City Berlin ambassador and Rector of ESCP Europe Business School Berlin. The economist's research is…→

©ESCP EUROPE

Transfer – Stories29.10.2019 | Professor Andreas Kaplan is a Brain City Berlin ambassador and Rector of ESCP Europe Business School Berlin. The economist's research is…→"We have to be able to take everyone on the journey."

-

Transfer – Stories

Gudrun Piechotta-Henze

Transfer – StoriesIn time for the 2020/21 winter semester, ASH, the Alice Salomon University of Applied Sciences Berlin, is launching the first bachelor's degree to…→

Gudrun Piechotta-Henze

Transfer – StoriesIn time for the 2020/21 winter semester, ASH, the Alice Salomon University of Applied Sciences Berlin, is launching the first bachelor's degree to…→"We have to completely rethink nursing!" | 27.09.2019

-

Transfer – Stories

©Humboldt-Universität zu Berlin/Matthias Heyde

Transfer – StoriesThe courses offered by the HUWISU Summer University are varied and exciting, the target group is international: students from abroad who come to…→

©Humboldt-Universität zu Berlin/Matthias Heyde

Transfer – StoriesThe courses offered by the HUWISU Summer University are varied and exciting, the target group is international: students from abroad who come to…→When Berlin becomes one large seminar room ... | 15.08.2019

-

Transfer – Stories

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/d/csm_bwasihun-vdo_558x314_c0d384ce60.jpg) [Translate to English:]

Transfer – StoriesThe literary scholar Dr. Betiel Wasihun was traveling for science. After stops in Heidelberg, Yale, and Oxford, it brought her to Berlin two years…→

[Translate to English:]

Transfer – StoriesThe literary scholar Dr. Betiel Wasihun was traveling for science. After stops in Heidelberg, Yale, and Oxford, it brought her to Berlin two years…→“Berlin is a perfect location. Especially if you don’t want to pursue just a single avenue of scientific work.” | 12.08.2019

-

Transfer – Stories

![[Translate to English:] Berlin University Alliance/Matthias Heyde [Translate to English:]](/fileadmin/_processed_/5/a/csm_Berlin_University_Alliance_Matthias_Heyde-558x314_4bc591ca3c.jpg) [Translate to English:] Berlin University Alliance/Matthias Heyde

Transfer – StoriesTogether we are stronger. And also more successful. As the "Berlin University Alliance," the Technische Universität Berlin, the Freie Universität…→

[Translate to English:] Berlin University Alliance/Matthias Heyde

Transfer – StoriesTogether we are stronger. And also more successful. As the "Berlin University Alliance," the Technische Universität Berlin, the Freie Universität…→Congratulations: The “Berlin University Alliance“ receives funding of the Excellence Strategy |19.07.2019

-

Transfer – Stories

![[Translate to English:] David Ausserhofer/IGB [Translate to English:]](/fileadmin/_processed_/6/f/csm_Hupfer__Michael_____R__David_Ausserhofer_588x314_6fef164e57.jpg) [Translate to English:] David Ausserhofer/IGB

Transfer – StoriesBerlin is one of the most water-rich cities in Germany. But climate change does not stop at the Havel, Spree or Wannsee either. Dr. Michael Hupfer is…→

[Translate to English:] David Ausserhofer/IGB

Transfer – StoriesBerlin is one of the most water-rich cities in Germany. But climate change does not stop at the Havel, Spree or Wannsee either. Dr. Michael Hupfer is…→"We're trying to take a look into the future." | 04.07.2019

-

Transfer – Stories

![[Translate to English:] Helena Lopes / Unsplash [Translate to English:]](/fileadmin/_processed_/b/6/csm_helena-lopes-1338810-unsplash_558x314_857802ad2f.jpg) [Translate to English:] Helena Lopes / Unsplash

Transfer – StoriesSend a digital lollipop or delicate fragrance notes via email or let the wind virtually blow against your face - research makes it possible. Learn…→

[Translate to English:] Helena Lopes / Unsplash

Transfer – StoriesSend a digital lollipop or delicate fragrance notes via email or let the wind virtually blow against your face - research makes it possible. Learn…→Experiencing the digital world with all senses | 18.06.2019

-

Transfer – Stories

![[Translate to English:] HZB/M. Setzpfandt [Translate to English:]](/fileadmin/_processed_/f/a/csm_LNDW_HZB_558x314_e1e3500ed5.jpg) [Translate to English:] HZB/M. Setzpfandt

Transfer – StoriesIn these times of fake news and pseudo-scientific publications, many people find it difficult to distinguish legitimate from dubious content. Only 54%…→

[Translate to English:] HZB/M. Setzpfandt

Transfer – StoriesIn these times of fake news and pseudo-scientific publications, many people find it difficult to distinguish legitimate from dubious content. Only 54%…→"Science needs to make us curious" | 11.06.2019

-

Transfer – Stories

![[Translate to English:] Tim Landgraf [Translate to English:]](/fileadmin/_processed_/0/7/csm_Car2CarEnergySharing_Tim_Landgraf_558x314_485bf716e9.jpg) [Translate to English:] Tim Landgraf

Transfer – StoriesBrain City Berlin is considered one of the leading locations in Germany working on artificial intelligence. About 30% of all German AI companies are…→

[Translate to English:] Tim Landgraf

Transfer – StoriesBrain City Berlin is considered one of the leading locations in Germany working on artificial intelligence. About 30% of all German AI companies are…→Fish, bees, and self-driving cars | 07.06.2019

-

Startup

![[Translate to English:] alvaro reyes on unsplash [Translate to English:]](/fileadmin/_processed_/4/4/csm_alvaro-reyes-unsplash_558x314_4d6fcfac3c.jpg) [Translate to English:] alvaro reyes on unsplash

StartupOb Kniffelspiel oder Sudoku – Gehirntraining gibt es bereits seit Jahrzehnten. Das Berliner Start-up NeuroNation bietet es per Web oder App. Das…→

[Translate to English:] alvaro reyes on unsplash

StartupOb Kniffelspiel oder Sudoku – Gehirntraining gibt es bereits seit Jahrzehnten. Das Berliner Start-up NeuroNation bietet es per Web oder App. Das…→Fitness training for the brain | 21.05.2019

-

Transfer – Stories

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/6/csm_Open-Access_Berlin-Partner_Wu__stenhagen_558x314_dd0c6e714d.jpg) [Translate to English:]

Transfer – StoriesScience and cultural heritage, freely accessible to everyone at any time on the Internet: The Open Access movement is promoting a paradigm shift in…→

[Translate to English:]

Transfer – StoriesScience and cultural heritage, freely accessible to everyone at any time on the Internet: The Open Access movement is promoting a paradigm shift in…→Knowledge for All - Open Access in Berlin | 28.03.2019

-

Transfer – Stories

![[Translate to English:] Thomas Rosenthal - Museum für Naturkunde Berlin [Translate to English:]](/fileadmin/_processed_/6/d/csm_Museum_fu___er_Naturkunde_Berlin_Thomas_Rosenthal_f11b8ba056.jpg) [Translate to English:] Thomas Rosenthal - Museum für Naturkunde Berlin

Transfer – Stories660 million euros in 10 years: The Natural History Museum Berlin - Museum für Naturkunde Berlin receives financial support for the further development…→

[Translate to English:] Thomas Rosenthal - Museum für Naturkunde Berlin

Transfer – Stories660 million euros in 10 years: The Natural History Museum Berlin - Museum für Naturkunde Berlin receives financial support for the further development…→Future of the Museum für Naturkunde Berlin | 14.01.2019

-

Transfer – Stories

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/c/csm_TU_Berlin_Cem_Avsar_558x314_4b07bcb055.jpg) [Translate to English:]

Transfer – StoriesSpace exploration is experiencing a revolution thanks to commercialization by such companies as Elon Musk's SpaceX. But did you know that more facets…→

[Translate to English:]

Transfer – StoriesSpace exploration is experiencing a revolution thanks to commercialization by such companies as Elon Musk's SpaceX. But did you know that more facets…→From Berlin to the moon: the space industry is booming in Berlin | 03.09.2018